Anuga FoodTec 2024: a compass for the food industry

This year’s Anuga FoodTec trade fair attracted 1,307 companies from 133 countries and nearly 40,000 trade visitors, reaffirming the event’s leading position as a showcase for future-oriented solutions in food technology.

This article is available for reading in Trade magazin 2024/6-7

Oliver Frese

chief operating officer

Koelnmesse

“At this year’s Anuga FoodTec, it became clear that true responsibility goes beyond day-to-day business and is now the driving force for sustainable and long-term growth”,

said Oliver Frese, chief operating officer of Koelnmesse.

Among the leading decision-makers registered for Anuga FoodTec, we could find the representatives of companies such as AB InBev, Arla Foods, Asahi, Conagra, Danone, DMK Deutsches Milchkontor, Dr. Oetker, Friesland Campina, General Mills, Kraft Heinz, Lactalis, McCain, Meiji, Mengniu, Mondelez, Müller, Nestlé, Nomad, Plukon, Saputo, Schreiber, Sprehe, Unilever and Yili.

133 countries, 1307 companies and nearly 40,000 trade visitors – that’s the balance of this year’s Anuga FoodTec

The industry’s commitment is visible

Anuga FoodTec has demonstrated that key themes such as responsibility, value creation, climate neutrality and food safety are shaping the direction the food industry is going – and that these are far from being merely short-term trends. The machinery and equipment on display gave an insight into innovative strategies for minimising food waste and waste water treatment. Another focus area of the trade show was the reduction of plastic consumption and the use of alternative packaging materials. Participants also had the opportunity to learn about the progress made in the production of plant-based foods.

For the first time, they were able to see a system that allows the production of cell-cultured foods on an industrial scale. Bearing in mind that a further increase in the world’s population could lead to a rise in demand for food and thus for plant-based proteins, Anuga FoodTec and the German Association for Alternative Protein Sources (BALPro e.V.) extended their cooperation in sustainable food innovation. The partnership seeks to support plant-based protein producers to jointly shape the sector and exploit its potential.

This year’s central themes were responsibility, value creation, climate neutrality and food safety

International FoodTec Award winners

The International FoodTec Awards recognise pioneering developments in food technology since 1994, in the fields of innovation, sustainability and efficiency. The awards were established by the German Agricultural Society (DLG) and its partners, and an international jury of experts from the research, education and practice domains selected the most forward-looking concepts. //

Winners and their innovations

International FoodTec Award – gold level

ANDRITZ Separation GmbH, Germany

ANDRITZ-Turbex: Upcycling of food by-products through cavitation extraction in the counter-current range

ANDRITZ-Turbex is a highly efficient extraction system for the production of functional nutrients and high-quality extracts from various plant materials and natural by-products, to support taste, colour, aroma and nutritional value in food formulations. //

Albert Handtmann Maschinenfabrik GmbH & Co. KG, Biberach a. d. Riß, Germany

ConProSachet-System: sustainable packaging from alginate

The Handtmann ConProSachet system is a new process for packaging liquid or paste-like products such as gels, beverages or sauces in pouches. Instead of prefabricated plastic film, it uses alginate for packaging. //

hs-tumbler GmbH, Quakenbrück, Germany

Trajectory mixer

Hs-tumbler uses a container that moves along so-called Lissajous curves, so that the special handling of the mixing material makes it possible to achieve a high quality mixing result in a shorter time; the technology eliminates “dead” zones within the tank.

watttron GmbH, Freital, Germany

SRHH: Digital sealing solution for sustainable and efficient packaging of dairy and food products

The cera2seal® digital sealing technology, in particular the SRHH (Sealing round heater hygienic) type, offers a new approach for sealing recycled single-material lids on packaged dairy products such as yogurt cups and other foods //

International FoodTec Award – silver level

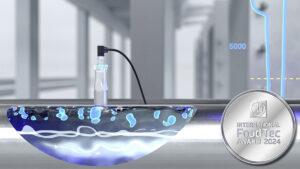

Lyras, Aalborg, Denmark

Raslysation™ technology: UV-based alternative process for the pasteurisation of opaque liquids that preserves quality and is sustainable

Lyras A/S has developed a non-thermal pasteurisation process, which is based on UV technology and is particularly suitable for pasteurising non-translucent liquids such as dairy products. The technology requires 90% less energy and about 60% less water. //

VETEC Anlagenbau GmbH, Verden/Aller, Germany

AEROMAT CROSS POWER: Transverse current principle – cross-flow innovation in horizontal air conveyance

AEROMAT CROSS POWER is a universal system for all types of heat treatment processes, including horizontal airflow drying, fumigation, cooling, cooking and baking of products in a lying position. //

TOMRA Sorting GmbH, Mülheim-Kärlich, Germany

Foreign Material Identification (FMID) &.TOMRA Insight: Foreign material identification using AI technology

TOMRA’s Foreign Material Identification (FMID) solution uses AI and cloud-based technology to improve food safety, quality and traceability while increasing process efficiency. The technology reduces the risk of food contamination and enhances food safety. //

Unison Process Solutions, Limerick, Ireland

HEIST (Heat Exchanger Integrity Self Test System): Automatic testing system for plate and pipe heat exchangers

HEIST is an innovative and patented system designed for the non-destructive integrity testing (NDT) of heat exchangers. Unlike conventional methods, daily inspection before production starts allows early detection of cracks or defects in heat exchanger plates. //

tsenso GmbH, Stuttgart, Germany

FreshIndex: Digital quality assurance for fresh products

FreshIndex offers a data-based quality control system and a fully automated supply chain in the fresh food segment. The system has a portable food spectrometer that quickly, accurately and non-destructively measures the intrinsic quality parameters of fresh products. //

Grasselli SPA, Albinea (RE), Italy

KSL-DV: Personalised horizontal fresh meat slicer

KSL-DV is an automatic horizontal slicer for slicing boneless meat – primarily poultry. The system is able to detect the size and shape of each incoming product and adjusts the slicing process to maximise the output and quality of the cut product. //

Maschinenfabrik Seydelmann KG, Stuttgart, Germany

All-in-one – Cutting drum for AU 200 U universal meat grinder

The AU 200 U universal meat grinder processes fresh meat and frozen meat (until -25ºC) without changing the knife set or the grilling grid, either simultaneously or with a little time delay. Raw material processing is contact-free.//

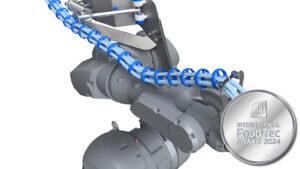

Murrplastik Systemtechnik GmbH & Stäubli, Oppenweiler, Germany

HygienicLine Dynamics cable retraction system for hygienic areas

FDA-compliant and hygienically designed HygienicLine Dynamics cable retraction system is the ideal choice for hygiene-sensitive industries such as the food industry. The use of stainless steel and high-performance plastics guarantees a smooth and abrasion-free surface. //

Hosokawa Alpine AG, Augsburg, Germany

Sugarplex SX Flow: Single-stage manufacturing of long shelf life icing sugar

In Sugarplex SX Flow a conditioned atmosphere is created during the milling process, meaning that the specific moisture content of the air and the time the freshly milled sugar spends in the milling chamber can be precisely monitored. //

Baumer Electric AG, Frauenfeld, Switzerland

PAD20: Analysis sensor for the detection of air and gas bubbles to prevent food waste and pump damage

With the Baumer PAD20 analysis sensor, the system detects when the fruit container is empty, e.g. during yogurt production. The sensor provides digital “insight” into the piping and can also detect air and gas bubbles in liquids.//

Related news

Related news

Nestlé to sell remaining ice-cream assets but commits to Froneri venture

🎧 Hallgasd a cikket: Lejátszás Szünet Folytatás Leállítás Nyelv: Auto…

Read more >