Hydrogen could soon replace natural gas in brick production

Wienerberger and the University of Miskolc are working on a globally pioneering development for sustainable brick production. In the drying equipment of the building materials manufacturer’s factory in Tiszavasvár, the drying process prior to firing was carried out using 100 percent hydrogen in a burner under real industrial conditions. Under laboratory conditions, the firing of the brick was also achieved using pure hydrogen. Based on the results of the experiments, the replacement of natural gas in the ceramic industry may receive new impetus, which could result in a significant reduction in carbon dioxide emissions.

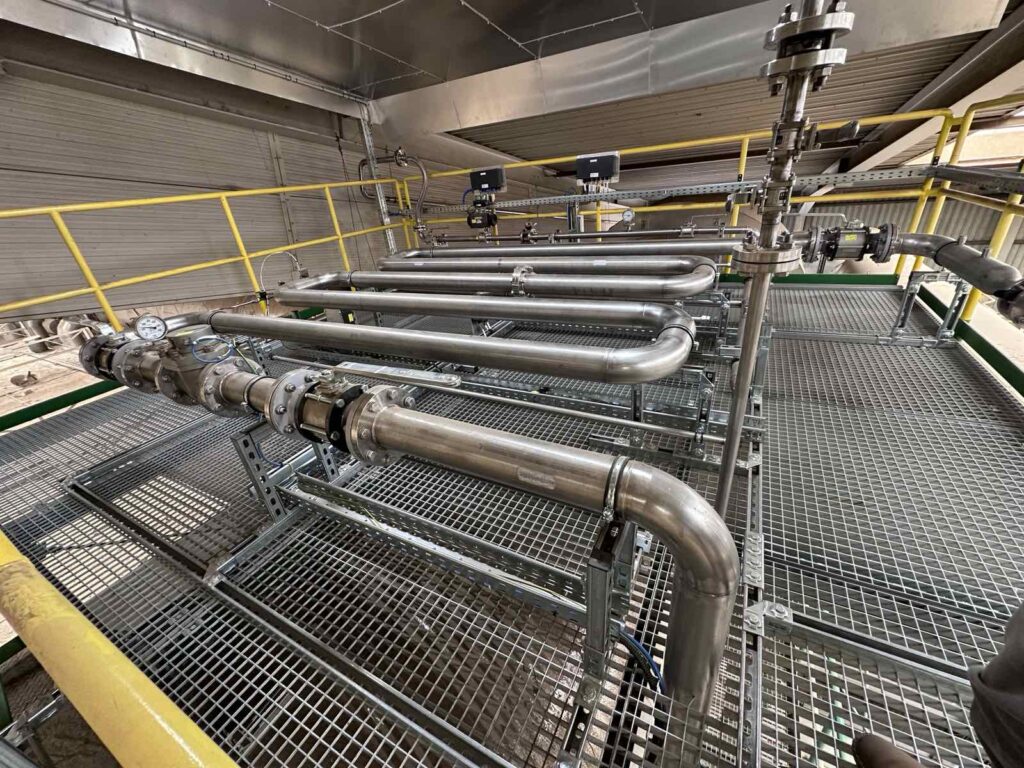

A new significant milestone has been reached in the greening of Wienerberger Zrt.’s Hungarian production. The building materials manufacturer, together with the University of Miskolc and the German burner manufacturer Scharr-TEC GmbH, successfully carried out a drying process prior to ceramic firing in the quick-drying equipment of the company’s brick factory in Tiszavasvár using only hydrogen.

A new significant milestone has been reached in the greening of Wienerberger Zrt.’s Hungarian production. The building materials manufacturer, together with the University of Miskolc and the German burner manufacturer Scharr-TEC GmbH, successfully carried out a drying process prior to ceramic firing in the quick-drying equipment of the company’s brick factory in Tiszavasvár using only hydrogen.

The current series of experiments proved that, after the previously achieved 25% mixed hydrogen ratio, it is now possible to practically completely replace natural gas in the brick drying and firing process. The technology is particularly valuable because it can also be achieved through the so-called retrofit conversion of existing infrastructures. The essence of this is that instead of replacing the entire technology, the existing equipment can be modernized, which means significant cost savings.

Related news

A third of Hungarians would completely isolate themselves from their neighbors

🎧 Hallgasd a cikket: Lejátszás Szünet Folytatás Leállítás Nyelv: Auto…

Read more >International leader arrives to lead MET

🎧 Hallgasd a cikket: Lejátszás Szünet Folytatás Leállítás Nyelv: Auto…

Read more >Wienerberger presented a bricklaying robot in Hungary

🎧 Hallgasd a cikket: Lejátszás Szünet Folytatás Leállítás Nyelv: Auto…

Read more >Related news

Impossible Foods featured on the “Best in Business” list again this year

🎧 Hallgasd a cikket: Lejátszás Szünet Folytatás Leállítás Nyelv: Auto…

Read more >Farewell day at the 60th anniversary EuroShop trade fair

🎧 Hallgasd a cikket: Lejátszás Szünet Folytatás Leállítás Nyelv: Auto…

Read more >